Winters at Southwest Marquees

Here at South West Marquees, we proudly own and maintain all of our equipment. This allows us to guarantee timely deliveries and perfect condition marquees for any event. We spend our downtime designing and manufacturing unique furniture, decorations and marquee accessories. And, we have also been expanding our main yard year-on-year, carrying out all major works in-house.

The Yard

When we first moved to Castle Hill Farm in 2008, the yard consisted of a bungalow, 3 barn buildings and a silo.

By 2009, we had re-built one of the older barns, created a lorry-suitable entrance, sectioned off the bungalow, added a large staff parking area with suitable entrance and added a fully kitted-our office.

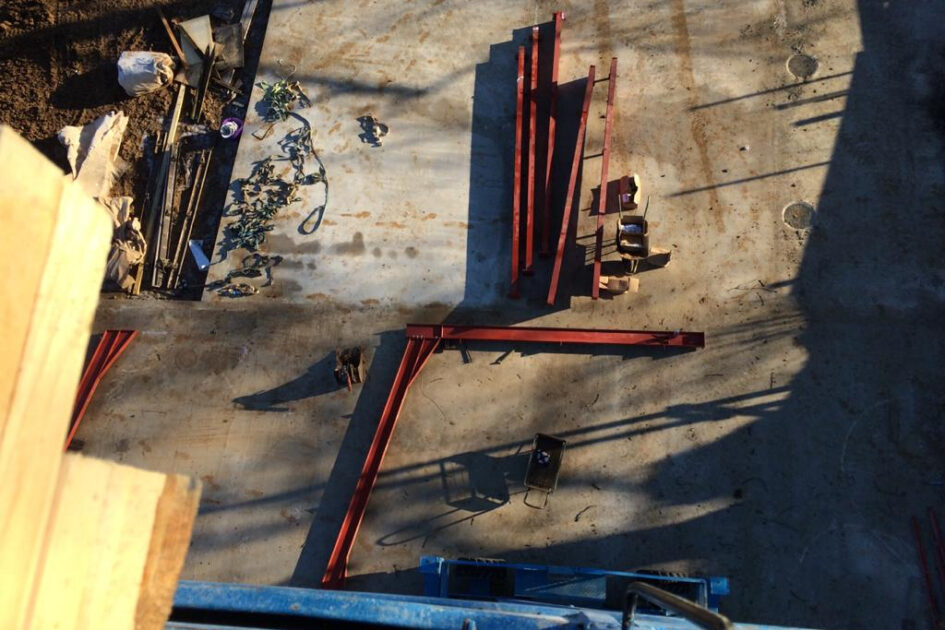

Fast forward to 2020 and we’ve expanded our yard yet again. It now includes 12 large barns or lean-to’s, each of which features custom-built storage facilities for our variety of stock. We also have a large manufacturing floor which is fully insulated and kitted out with everything we need to manufacture and repair PVC. A large rainwater harvesting system, staff car park, fleet vehicle parking area, office car park and fully concreted yard complete. We are proud to say that everything we have added to the site has been built in-house by our full-time staff.

Electricals

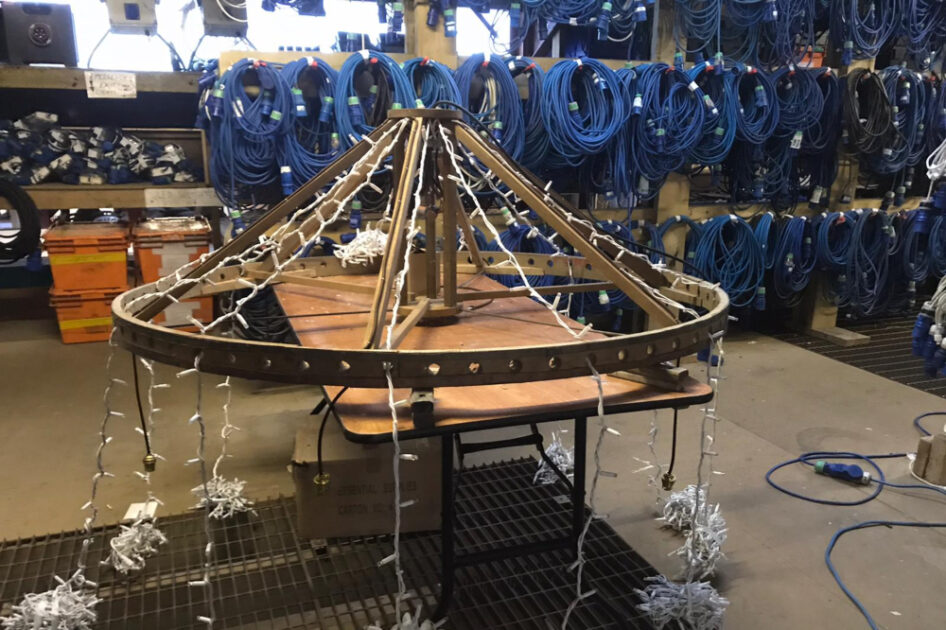

We ensure that all of our electrical equipment is thoroughly checked before every use and before it is packed away. We also PAT test our equipment in-house once a year. In 2019, we manufactured numerous lighting decorations, including our Edison Cartwheels, Edison Ladders and Rustic Edison Bar. In 2020, we are delighted to announce the Edison Cartwheel Lighting Rig with a fairy light roof canopy.

We are constantly asked to install the client’s own ladders and kit them out with lights or decorations. In Winter 2019, we manufacture our own collection of rustic ladders complete with LED Edison Lights and Artificial Ivy Foliage.

Manufacturing Floor

We have always undertaken minor repairs to our PVC using a hand welder and other minor tools. This includes everything from small tears through to replacing hooks and loops. For lining damage, we use a sewing machine which has also been used to make smaller items since the beginning. In 2018, we invested in a high-frequency welder which enables us to manufacture our own roofs, walls and repair damaged PVC on a larger, higher-quality scale.

- Repairing a small split in a 3m roof with our small heat welder

- Our first batch of panoramic windows being put together on the high-frequency welder

- Mass producing new straps and ties for use during our busiest periods